Axtra.Insight connects every stage of the workflow, from Volume to Cure, providing real-time process data, analytics, and full traceability. It ensures that every part produced is validated, documented, and compliant with production or regulatory standards.

It provides comprehensive process monitoring and reporting across 155+ sensors.

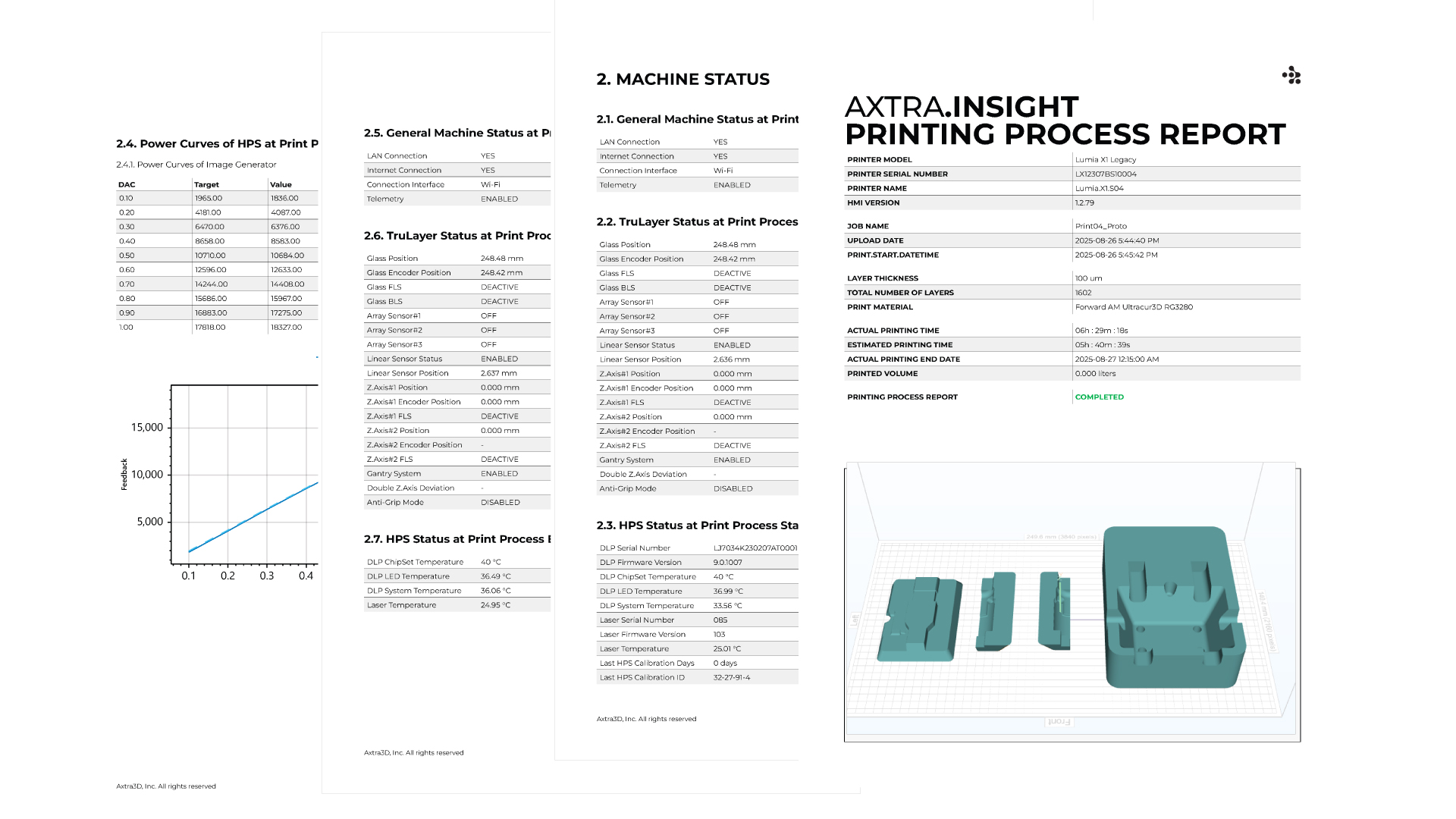

For Lumia X1, it tracks general job information, printing process details, machine and TruLayer sensor status, HPS laser and DLP power and temperature, and full print job history. It captures detailed per-layer data, including TruLayer timing, Z-axis encoder readings, and system temperatures, as well as complete print job metrics for both TruLayer and HPS systems.

This enables full traceability, process validation, and actionable insights for repeatable, high-quality additive manufacturing.

It is enabled to report on all Axtra devices, including the Lumia.X1, Axtra.Wash and Axtra.Cure.