Axtra3D Expands Material Offering with Production-Grade Resins Optimized for Precision and Performance

November 18, 2024, Charlotte, NC – Axtra3D® is excited to announce the qualification and immediate availability of 6 new materials designed to meet diverse industrial needs and application-specific demands. The expanded resin portfolio incorporates direct customer feedback and further aligns Axtra3D solutions with real-world applications.

Rajeev Kulkarni, CSO at Axtra3D, indicates, “These six resins have been carefully engineered to optimize performance with Axtra3D’s Lumia X1 Hi-Speed SLA platform, empowering users to achieve high precision, durability, and functional properties. This underscores Axtra3D’s commitment to providing adaptable, high-performance solutions for industries ranging from automotive and industrial manufacturing to consumer goods and healthcare.

We continue to improve our Hi-Speed SLA offerings by staying true to our foundational value proposition of no tradeoffs in precision, accuracy, surface finish, and print throughput when developing new materials and solutions.

With these latest additions, Axtra3D further strengthens its core business model by building a robust ecosystem of top-tier material partners in the additive manufacturing industry. We are excited to welcome Arkema and Spectroplast to our expanding material partner ecosystem and deepen our collaborations with Forward AM and Loctite.”

The new materials with immediate availability are:

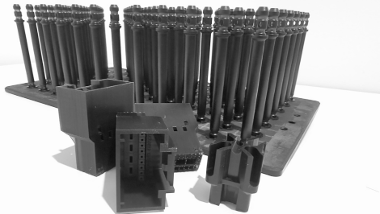

N3D-FR512, Arkema

Flame Retardancy for Electrical Applications– A fire-retardant, high-strength material with an HDT of 170° and achieves a UL-94 rating of V-0 at 0.8mm while maintaining good print accuracy with fine feature parts. This material is a liquid at room temperature and is designed for demanding electrical connector applications where flame retardance is essential.

TruSil-X50 for Axtra3D, Spectroplast

Bringing Real Silicone Flexibility– TruSil-X50 is Axtra3D’s answer to industries needing a true silicone material that combines flexibility with resilience. Developed specifically for rubber-like applications, such as seals, gaskets, prosthetics, and audiology components, this resin mimics the properties of traditional silicone, with the added advantage of 3D-printed precision and customization. This material caters to applications where flexibility, durability, and skin-safe properties are paramount, expanding Axtra3D’s portfolio into new frontiers in healthcare and consumer goods.

Loctite IND 249, Henkel

Precision for Complex Geometries– This material is engineered for intricate, fine-featured designs with high strength, impressive stiffness and thermal durability. It is a low-viscosity material with exceptionally high green strength to enable ease of processing. This material supports complex geometries, making it a strong choice for connectors manufacturing aids, and other production-grade applications.

Ultracur® ST 45 B, Forward AM

Expanding Silicone Casting Possibilities- Developed with silicone mold applications in mind, Ultracur ST 45 B is a highly versatile resin that combines strength and precision, making it ideal for molds designed for silicone casting. Leveraging the advanced imaging of the Lumia X1, this resin delivers exceptional thermal stability, high detail reproduction, and ease of demolding, attributes crucial for silicone molds requiring sharp precision and flawless surface finish. This balanced performance makes ST 45 B a robust choice for mold makers and other high-detail, high-precision applications.

Ultracur® RG 1100, Forward AM

Broadening Low-Pressure Molding Applications– Recognizing the need for materials that withstand demanding molding environments, Axtra3D developed Ultracur RG 1100 with a focus on low-pressure molding, particularly for large, durable parts like shoe soles and other oversized components. This high-strength, polyurethane-based resin provides mechanical properties comparable to injection-molding grades, yet its low-viscosity profile makes it suitable for applications where high-viscosity, rubber-like materials would fall short. With RG 1100, users can achieve impressive durability and strength, ideal for automotive, heavy equipment, and other engineering applications.

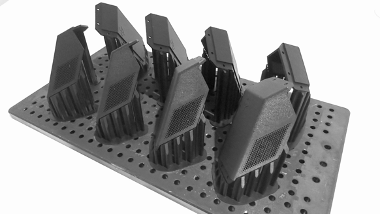

Loctite IND 3380, Henkel

Electrostatic Dissipative (ESD) Properties– Engineered to meet the demands of electronic manufacturing and tooling, this material offers a unique combination of high accuracy, fine detail printing, and ESD properties. This versatile, stiff resin provides exceptional dimensional stability, making it ideal for applications such as jigs, fixtures, and tooling where control over static discharge is crucial. Additionally, IND 3380 withstands high-temperature environments and performs well under low-pressure conditions, ensuring reliable use in electronics and precision industrial settings.

Highlighting Axtra3D’s Commitment to Customer-Centric Solutions

“These new resins reflect our commitment to designing materials that meet challenging customer needs, staying true to our no-compromise approach. By collaborating closely with customers, we ensure that every new material has a clear end-use application, accelerating innovation and aligning with the precision and performance demands of key industries.” said Rajeev Kulkarni, CSO at Axtra3D.

About Axtra3D

Company

Based in the US and Italy, Axtra3D is a global company specializing in Hi-Speed SLA systems that eliminates tradeoffs between print throughput, accuracy, feature resolution, and surface finish, typically found in traditional SLA or DLP systems.

The flagship Lumia X1 Hi-Speed SLA system by Axtra3D represents a significant advancement, combining its Hybrid PhotoSynthesis resin polymerization process with TruLayer, a layer separation technology. HPS utilizes both a laser and a DLP to image simultaneously, while TruLayer enables rapid detachment of the active print layer, resulting in a 20X throughput improvement while preserving the accuracy and fidelity of SLA parts.

With a curated material portfolio, Axtra3D has developed over 15 certified solutions for industries such as Industrial, Healthcare, and Dental, serving a global customer base. These solutions range from direct-use ceramic molds to end-use electrical connectors, industrial parts, dental prosthetics, medical devices, jewelry patterns, and more. Axtra3D’s systems are available in North America, the EU, and Japan, and a broad range of customers have already benefitted from its diverse range of applications.

Axtra3D operates with two business models.

Axtra Solutions™: This model provides fully optimized, turnkey 3D printing solutions. Customers receive complete print profiles fine-tuned for maximum performance and reliability, supported by Axtra3D’s Applications team and quality material partners.

Axtra OpenAccess™: This model further builds on Axtra Solutions™ and allows customers the flexibility to experiment with new materials and applications. It supports innovation and adaptability, enabling added flexibility.

Contact

Meredith Scott

M&C Project Manager

Rajeev Kulkarni

Chief Strategy Officer

LinkedIn: https://www.linkedin.com/company/axtra3d

YouTube: https://www.youtube.com/@axtra3d320