Axtra3D® has long been recognized for its precision, reliability, and repeatability in photopolymerization 3D printing.

By combining the accuracy of a laser with the speed of DLP projection in a single optical system, Axtra3D eliminated traditional trade-offs between resolution, surface quality, and speed, enabling manufacturers to scale fully optimized solutions using its Lumia X1 3D printer.

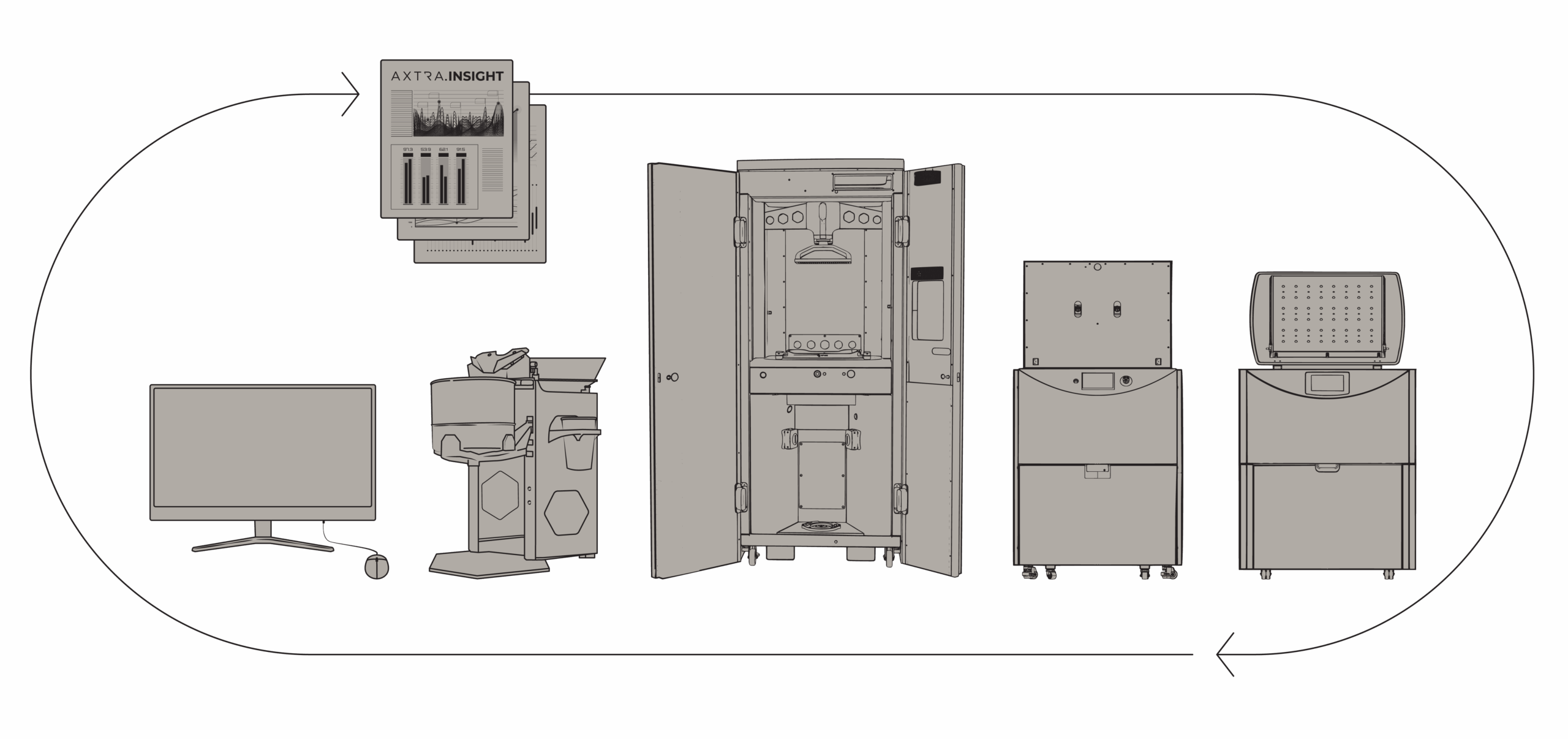

By connecting setup, printing, washing, drying, curing, and thermal treating, Axtra3D ensures each step reinforces the next. Material profiles, printer settings, and curing recipes are optimized holistically, eliminating variation and ensuring parts consistently meet specifications. This integrated ecosystem of hardware, materials, and software allows manufacturers to operate with confidence, achieving precise, repeatable, and fully connected production workflows.

Many manufacturers struggle to move from successful prototyping to true production-ready 3D printing due to variability in materials, environmental conditions, and printer calibration.

Disconnected workflows across printers, wash stations, and curing units create inconsistencies in repeatability, surface quality, and mechanical performance, making part validation for regulated or end-use applications difficult.

Introducing new resins or designs often requires revalidating the entire process, consuming time and limiting agility. Without a fully connected and data-driven system, teams are forced to manage fragmented processes manually, reducing efficiency and stifling innovation.

Axtra.Workflow™ resolves these challenges and offers individual products that create an intelligent and harmonized ecosystem of hardware, materials, and software.

All elements from build setup to final parts are fully connected and optimized for reliability, creating a backbone that enables users to validate their workflows. Each capability within the workflow enables a very specific customer benefit.

Elements of the Workflow |

Solution Capability it Creates |

Customer Benefit |

|---|---|---|

Each stage builds on the previous one |

Fully Dialed |

Ensures accuracy

|

Robust design with continuous improvement |

Reliable |

Ensures dependability

|

Develops a learning model from all previous prints |

Repeatable |

Ensures consistency

|

Layer level insights verify performance |

Validated |

Ensures assurance

|

Sensor data tracks every step of the entire process |

Traceable |

Ensures accountability

|

Production ready and automation capable |

Scalable |

Ensures growth

|

Closed loop and data guided workflow |

Insight driven |

Ensures clarity

|