New Investment in HPS Technology Enhances LPE’s Capabilities for High-Performance Applications in Demanding Sectors

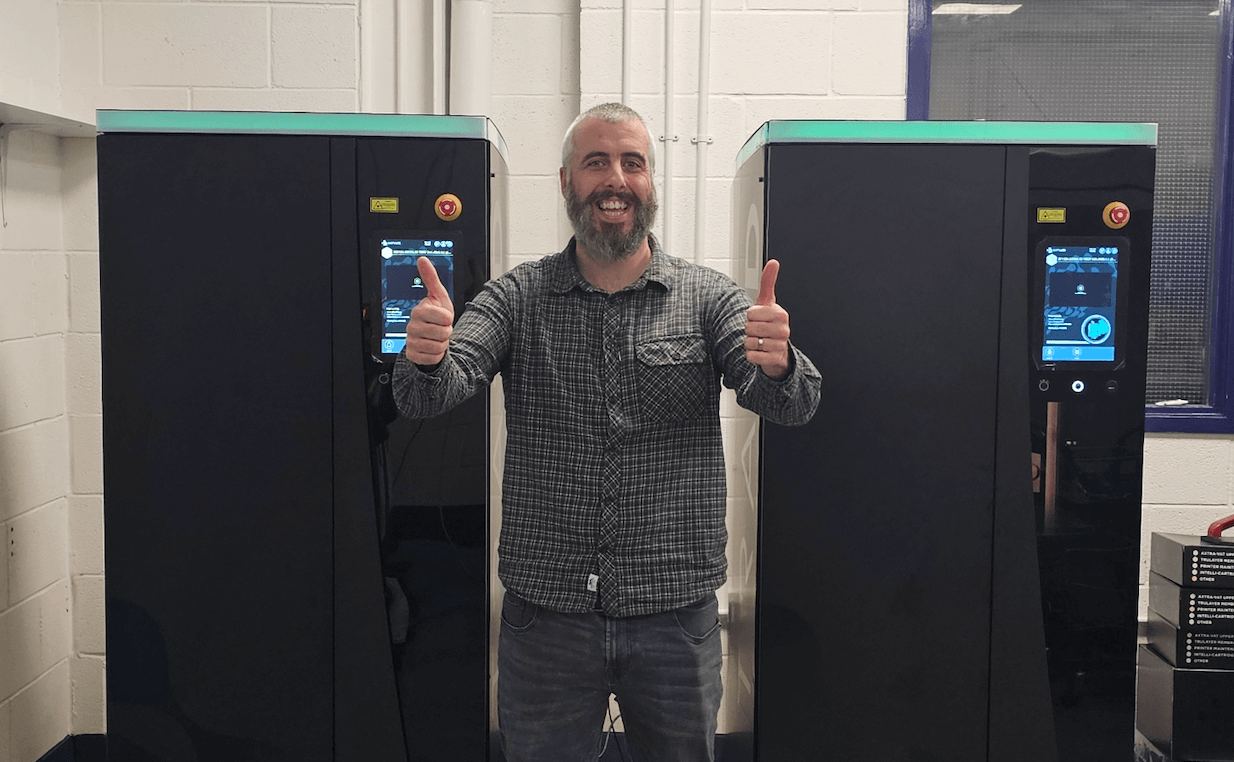

November 20, 2024, Charlotte, NC – Laser Prototypes Europe (LPE), a pioneering additive manufacturing service provider with over 30 years of expertise, is further enhancing its 3D printing capabilities by acquiring a second Lumia.X1 3D printer from Axtra3D. This investment underscores LPE’s commitment to staying at the cutting edge of rapid prototyping and manufacturing solutions across sectors, including automotive, aerospace, medical, and consumer goods. LPE’s adoption of Axtra3D’s Hybrid PhotoSynthesis (HPS) technology is a response to the growing demand for highly accurate, repeatable, and high-performance 3D-printed parts.

Patrick Walls, Engineering Director at LPE, explained the decision to add another Lumia.X1 to their fleet: “The demand from our customers for this cutting-edge technology has been increasing, and this expansion enables us to boost our production capacity while reducing turnaround times. The unique material properties offered by HPS technology open new applications for 3D printing, allowing our customers to explore possibilities they hadn’t previously considered. At LPE, we are committed to investing in pioneering technologies to stay at the forefront of the industry, providing our clients with the latest, most advanced manufacturing solutions.”

LPE has built a reputation as a trusted additive manufacturing partner with a wide range of services, from CAD analysis and consultation to full finishing and certification. With over 20 advanced in-house machines and a team of 40 skilled professionals, LPE leverages cutting-edge technologies to meet complex geometric and large-scale production demands. The Lumia.X1’s rapid production capabilities enhance LPE’s speed and efficiency, enabling the company to deliver high-quality models within days.

Since 1991, LPE has been dedicated to fostering strong client relationships, prioritizing fast, reliable, and customer-centric services. This latest expansion aligns with LPE’s ongoing mission to lead in the additive manufacturing industry by integrating advanced, high-precision technologies.

Andreas Tulaj, SVP of EU Revenue at Axtra3D, said “Our partnership with LPE represents a significant step forward in delivering unmatched quality and speed across various high-demand sectors. With their continued investment in Axtra3D’s Lumia.X1 and its HPS technology, LPE is able to achieve exceptional surface finishes, precise geometries, and high throughput—all essential for meeting the rigorous standards of motorsport and aerospace applications. Their use of high-performance photopolymer resins, like Forward AM’s Ultracur 3280 and High Temp 300-AMB, underscores the value of our collaboration in advancing end-use part capabilities”.

About Axtra3D

Company

Based in the US and Italy, Axtra3D is a global company specializing in Hi-Speed SLA systems that eliminates tradeoffs between print throughput, accuracy, feature resolution, and surface finish, typically found in traditional SLA or DLP systems.

The flagship Lumia.X1 Hi-Speed SLA system by Axtra3D represents a significant advancement, combining its Hybrid PhotoSynthesis resin polymerization process with TruLayer, a layer separation technology. HPS utilizes both a laser and a DLP to image simultaneously, while TruLayer enables rapid detachment of the active print layer, resulting in a 20X throughput improvement while preserving the accuracy and fidelity of SLA parts.

With a curated material portfolio, Axtra3D has developed over 15 certified solutions for industries such as Industrial, Healthcare, and Dental, serving a global customer base. These solutions range from direct-use ceramic molds to end-use electrical connectors, industrial parts, dental prosthetics, medical devices, jewelry patterns, and more. Axtra3D’s systems are available in North America, the EU, and Japan, and a broad range of customers have already benefitted from its diverse range of applications.

Axtra3D operates with two business models.

Axtra Solutions™: This model provides fully optimized, turnkey 3D printing solutions. Customers receive complete print profiles fine-tuned for maximum performance and reliability, supported by Axtra3D’s Applications team and quality material partners.

Axtra OpenAccess™: This model further builds on Axtra Solutions™ and allows customers the flexibility to experiment with new materials and applications. It supports innovation and adaptability, enabling added flexibility.

Contact

Meredith Scott

M&C Project Manager

Rajeev Kulkarni

Chief Strategy Officer

LinkedIn: https://www.linkedin.com/company/axtra3d

YouTube: https://www.youtube.com/@axtra3d320